Introduce:

In a fast-paced manufacturing world, the need for reliable, efficient fastening solutions cannot be underestimated. Fastener molds are the unsung heroes of every industry holding structures and products together. While there are many fastening options on the market, machine screw overpunch technology stands out as a game changer. This advanced technology, combined with fastener molds and screw tools, has revolutionized the fastening process, delivering superior reliability, strength and precision.

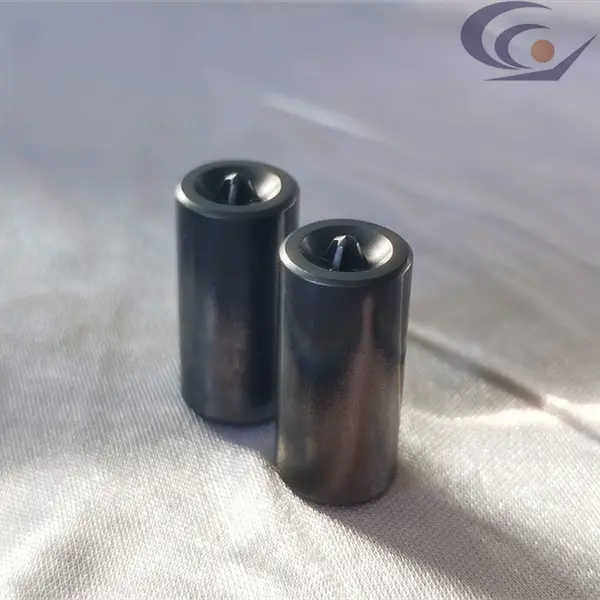

1. Understand the secondary punching technology of mechanical screws

Machine screw second punch technology is a cutting-edge technology that changes the way fasteners are made and used. The technique involves creating fasteners using a two-step process. In the first step, a fastener mold is used to form the basic shape and structure of the screw. Then, use a second punch to add further benefits to the fastener, such as high precision, additional threads, or special features. This innovative approach ensures fasteners are created that meet the exact requirements of different applications, thereby enhancing the overall performance and functionality of the product.

2. Fastener Molds: Accuracy and Consistency

Fastener molds play a vital role in manufacturing high-quality fasteners using machine screw secondary punch technology. These molds are intricately designed to precisely shape fasteners made from a variety of materials, including steel, aluminum or specialty alloys. They ensure consistency in size, shape and structural integrity regardless of output. Fastener molds are designed to withstand the rigors of the mass production process, ensuring fasteners are perfectly replicated time and time again.

3. Threading Tools: Increase Efficiency and Versatility

Screw tools are essential when assembling and fastening components in various industries. Whether it’s a hand wrench, air driver, or automated assembly machine, screw tools allow workers to tighten screws consistently and efficiently. Combined with machine screw secondary punching technology, the screw tool acts as the final piece of the puzzle, ensuring fasteners are securely tightened for optimal structural integrity. These tools are designed to provide versatility in terms of torque control, speed adjustment, and adaptability to different fastener sizes and types.

4. Advantages and Applications

The combination of machine screw secondary punch technology, fastener dies and screw tools offers numerous benefits to a variety of industries. This advanced technology improves product quality, durability and performance by manufacturing fasteners with high precision and customized functionality. Additionally, increased efficiency in the fastening process means reduced assembly time and labor costs, thereby increasing productivity and profitability.

Mechanical screw secondary punch technology has a wide range of applications in various fields, from the automotive and aerospace industries to electronics manufacturing and construction. It ensures component integrity, provides stability in high-stress environments, and allows for easy disassembly when needed.

In conclusion:

Machine screw secondary punch technology combined with fastener dies and screw tools represents a major leap forward in fastening solutions. The ability to produce fasteners with high precision and custom functionality enables manufacturers to meet the growing needs of different industries while ensuring maximum strength and durability of the product. Adopting this technology is expected to increase efficiency, reduce costs and increase customer satisfaction. It is truly revolutionizing the world of fastening, leading innovation and setting new standards for reliable, efficient assembly processes.

Post time: Nov-08-2023